Content Center

- View All Content

- Videos

- White Papers

- 4 reasons to upgrade to modern motor systems

- ABB Energy Efficiency White Paper

- Designing for Optimum Energy Management

- Digital Manufacturing Journey

- Energy Efficiency Playbook

- Energy efficiency - What You Measure Matters

- How to Read a NEMA Motor Nameplate

- How to extend the life of your motor bearings

- Improving end-to-end system efficiency

- NEMA vs. IEC Efficiencies

- Overcoming HVAC Challenges In Your Facility

- Success Stories

- Articles

- Flyer

- Brochure

- Interactive Brochure

- Podcast

- ABB NXR US Motor, the High Horsepower Solution

- Advantages of a DC to AC Motor Conversion

- Are Your HVAC Motor Bearings Protected?

- Condition Monitoring Using ABB Ability

- Do you have the right motor for your VFD controlled application?

- Drive system efficiency

- Eco-design

- Embrace the Digital

- Frequently Used Motor Terms

- How Motors Impact Water Operations

- IEC and What it Means in the US

- IEEE Standards & What You Should Know

- Induction vs. Synchronous

- Industrial Cold Storage

- Misconceptions Between NEMA and IEC efficiencies

- Protect Your High Voltage Motor Using ABB LEAP Analysis Tool

- When to Start Thinking Severe Duty Motors

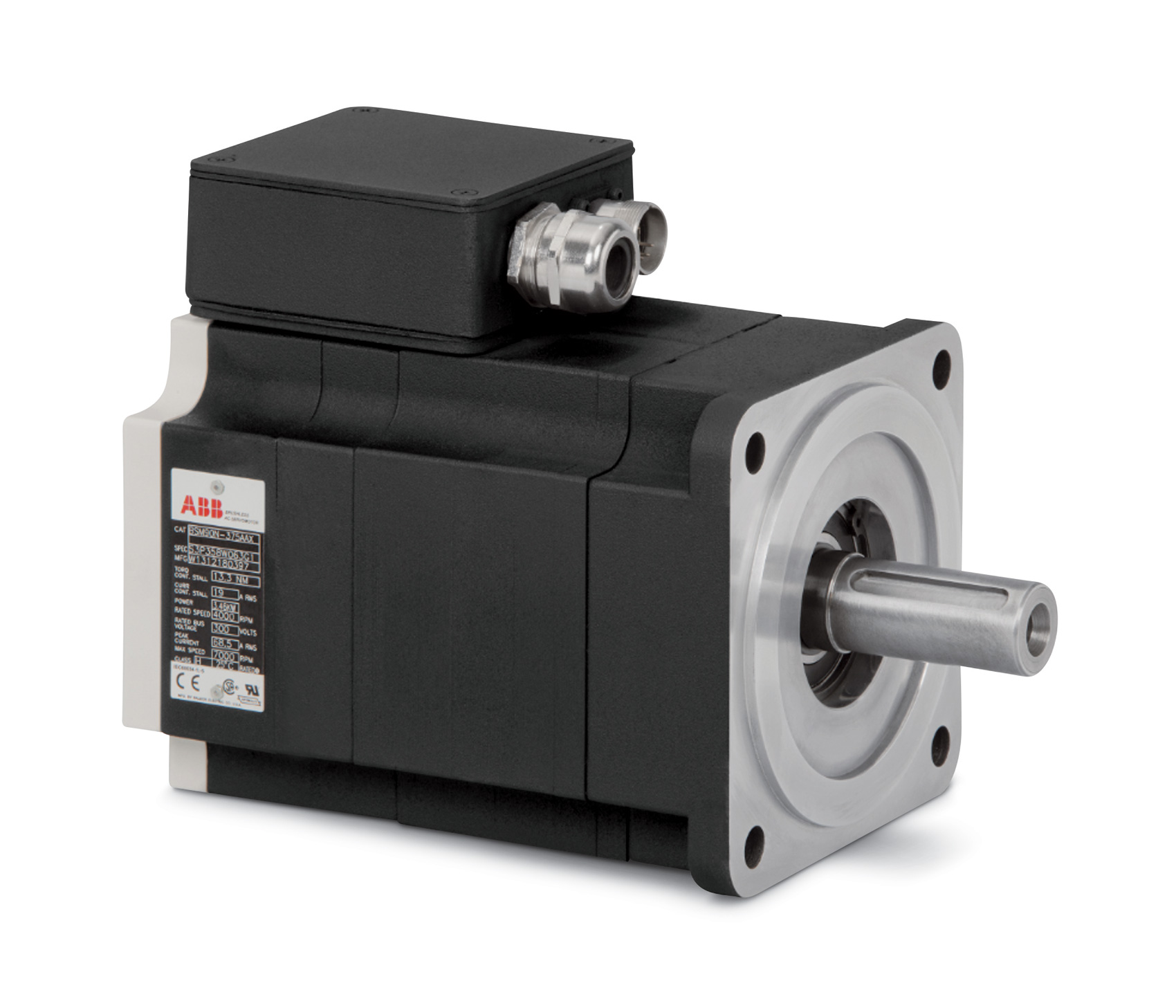

The BSM B-Series offers all the performance and reliability our customers have come to expect from ABB servo motors. It has the performance of rare earth magnet motors but without the rare-earth magnets. The rotor is designed around ferrite magnets. This environmentally friendly material is less susceptible to sourcing and pricing pressure. For high precision applications, this motor offers exceptionally low cogging with minimal torque ripple. For machining applications in particular, this translates to a better finish on machined surfaces (increased quality).

Features

- Sustainable ferrite non-rare earth magnet material

- Torque range: 14.4 – 177 lbs-in (1.63 – 20Nm)

- Inertia range: 0.0031 to 0.0666 lb-in-s2 (3.51 – 75.2 kg-cm2)

- High rotor inertial for matching heavier machine inertia loads

- Optional forced air cooling to extend torque capability for additional motor performance

- Windings potted for additional voltage protection that improves reliability and heat transfer

- Design is interchangeable with C and N series for machine design versatility

- Rugged industrial construction

- cURus/CE certified quality design

Common applications

- Fast cycle times

- Medium to high inertia applications

- Large loads

- Machine tools

- Labeling

- Material handling

- Winding

Common industries

- Semiconductor

- Packaging

- Food and beverage

- Factory automation

- Medical

- Robotics